8 Simple Techniques For Premier Aluminum Llc

Premier Aluminum Llc Things To Know Before You Get This

Table of ContentsExcitement About Premier Aluminum LlcLittle Known Questions About Premier Aluminum Llc.The 20-Second Trick For Premier Aluminum LlcGet This Report about Premier Aluminum LlcPremier Aluminum Llc - Questions

When choosing a light weight aluminum foundry for your production needs, it's crucial to study several factors. One of one of the most crucial elements to consider is the experience and proficiency of the shop. Picking a factory that has the appropriate knowledge of the aluminum casting process, and the portfolio to reveal for it, aids to have an effective end result for your project.Having the experience and industry understanding to engineer your castings for optimal production and high quality end results will certainly enhance the task. Producing light weight aluminum spreading calls for a facility collection of procedures to accomplish the appropriate results. When picking a brand-new light weight aluminum shop to companion with, ensure they have extensive sector experience and are educated regarding all facets of the aluminum spreading process: design, production, material analysis, and product screening.

The shop needs to additionally have a tried and tested track document of supplying remarkable products that meet or go beyond consumer expectations. Quality control needs to likewise be at the top of your list when picking a light weight aluminum shop. By functioning with a certified shop that complies with the requirements for high quality control, you can protect the integrity of your item and ensure it meets your requirements.

Rumored Buzz on Premier Aluminum Llc

This certain procedure can be automated and repeated. Numerous elements that very complicated forms can be produced using this procedure. Big volumes of components can be generated in simply a short period of time. Prior to you start searching for a trusted light weight aluminum die wheel, there are some essential points that you require to do.

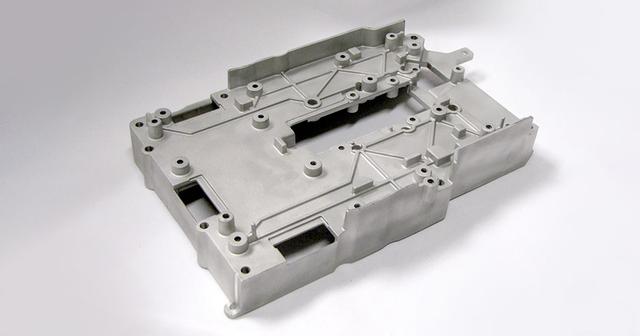

You have to ask on your own what sort of light weight aluminum die castings you call for. After identifying what you require, you need to specify the specifications of the aluminum die spreadings you require. Determine the weight, thickness, dimension, and various other specifications of the aluminum die-cast you call for. It would also be far better if you could draw and reveal all the dimensions of the light weight aluminum die-cast.

After having this information, you can start researching aluminum die-casting makers. You can do this by just inputting the keyword" Aluminum die casting manufacturers" on the Google search engine.

Several of the inquiries you require to ask on your own are whether they have experienced and well-trained operators, how long their company has been in operation, or if they have some achievements. You can frequently get the response to these inquiries from the supplier's internet site. You can investigate other websites or exterior resources to confirm if the information provided on the supplier's internet site is authentic.

Our Premier Aluminum Llc Ideas

An additional thing you need to think about is the supplier's ability to generate aluminum look at these guys die-casting items. Simply put, the volume of items the manufacturer can produce at a given time. Several of the critical questions you require to ask on your own are whether the maker can create a higher quantity or can the manufacturer fulfill your needs.

(https://www.interweave.com/plus_old/members/premieraluminum/profile/)What happens if your business needs 10,000 pieces of particular equipment parts from the producer within one month? You ordered this amount; nonetheless, the producer can only produce 5000 items of these device parts within one month (Aluminum Metal casting). Because of this, you won't have the ability to receive the amount that you buy on schedule

The 3-Minute Rule for Premier Aluminum Llc

It is vital that you should ask if the manufacturer is implementing an internal tooling process. In addition, you have to ask the supplier how much the price of in-house tooling is. The in-house tooling process, which allows you to develop distinct layouts and shapes can be an extra cost.

This element straight associates with the manufacturer's production ability. Casting Foundry. You have to look for a supplier that can guarantee quicker distribution of items.

This indicates that there are numerous choices that you can select from. That is why it is considerably suggested that you must select a manufacturer that can create various kinds of aluminum die-cast products.

Premier Aluminum Llc Can Be Fun For Everyone

Frequently, these light weight aluminum die-casting products will certainly require some decorations, machining, or completing touches. Having this in mind, you need to search for a maker that can implement a range of secondary finishing jobs when die spreading is done. Some instances of ending up operations include Chromating, CNC Machining, Sandblasting, Powder finish, Anodized, E-coating, Wet painting, Plating, and much more.

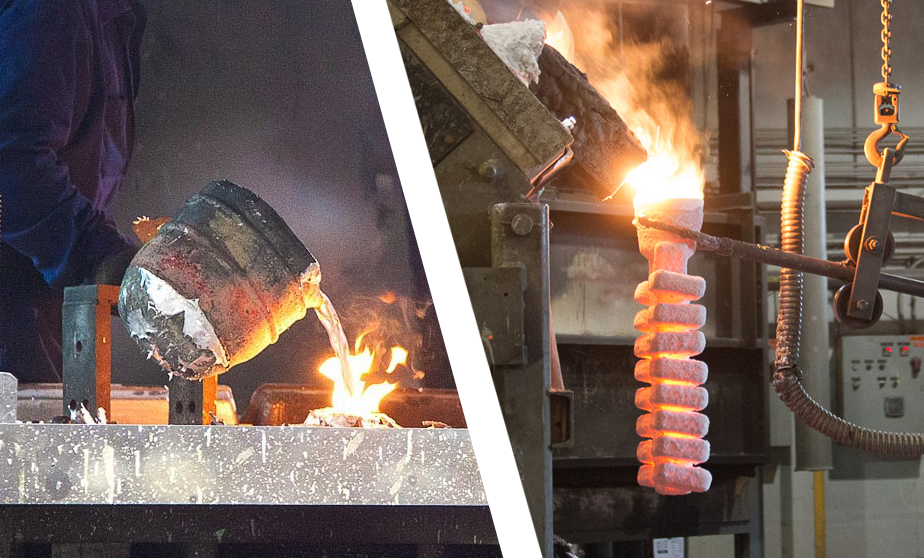

Die spreading is one of the most affordable, precise, and protean production procedures in the globe moment. The process entails suitable molten essence, under stress, right into an appropriate die (earth), and previously solidified it can be expelled and finished (if necessary) in a selection of means.